Introduction to weld neck flange

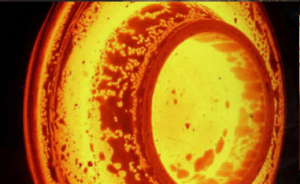

The weld neck flange, also known as the tapered hub flange, has a neck that smoothly transitions to a pipe and is designed for butt welding, ensuring a strong and seamless connection. It features a tapered neck with evenly spaced bolt holes on the flange plate, allowing it to be securely bolted to another flange.

By distributing stress from the pipe, it helps reduce stress concentration at the base of the flange. These flanges create a strong and reliable connection between two pipes or tubes and connect different valves and components in the piping system. Our weld neck flanges offer the advantages of a strong connection and excellent sealing performance. They are widely used in tough environments, including oil and gas, petrochemical, and power generation industries.

We are a specialized manufacturer that combines research, design, development, manufacturing, and sales of different types of pipe flanges. We adopt advanced production techniques and use high-quality domestic and imported materials. We can produce excellent pipe fittings according to GB, ASME, JIS, DIN, EN standards, and others. We also offer custom non-standard pipe fittings based on customer specifications. Please feel free to get in touch with us.

Weld neck flange application

We specialize in producing and exporting a wide range of weld neck flanges. Our flanges are suitable for severe conditions, including high-pressure environments, wide fluctuations in temperature and pressure, high-temperature applications, volatile and hazardous fluids, and low-temperature (below freezing) environments. The weld neck flanges we produce are widely used in many industries. Let’s take a look.

1. Pressure vessel and pipe connections

Our weld neck flanges are widely used to connect pressure vessels and pipelines in industries including oil, chemicals, natural gas, and power.

2. Boiler and heater connections

Our weld neck flanges are used to link the boiler body and pipe systems in the design and production of boilers and heaters, ensuring safe and reliable heat transfer.

3. Liquid and gas transport systems

Our weld neck flanges are used to connect pipeline systems that transport liquids and gases, such as in water supply, sewage treatment, and oil and gas transportation.

4. Marine engineering

Our weld neck flanges are widely used in marine engineering projects, including offshore platforms, breakwaters, docks, and underwater pipelines, to ensure the stability and reliability of marine structures.

5. Oil and gas exploration

Our weld neck flanges are used in oil and gas exploration for connecting drilling equipment and well systems, such as wellhead lines and casings.

6. Chemical equipment and process systems

Our weld neck flanges are frequently used in chemical equipment and process systems to connect reactors, distillation towers, separators, and more.

7. Food and pharmaceutical industries

Our weld neck flanges are used in the food and pharmaceutical industries to connect pipeline systems that transport food and medicine, ensuring product quality and safety.

8. HVAC systems

Our weld neck flanges are used to connect equipment like radiators, cooling towers, and fan coil units in heating and air conditioning systems.

9. Power and nuclear plants

Our weld neck flanges are commonly used in power plants and nuclear power stations to connect boilers, turbines, and steam generators.

10. Construction projects

Our weld neck flanges are widely used in the piping systems of construction projects, including water supply, drainage, and fire systems.

Weld neck flanges manufacturers

We are a top weld neck flange manufacturer in China. All our products are manufactured according to strict standards such as SHJ, HGJ, ANST, JIS, DIN, and ISO. We use materials such as 304, 321, 304L, 316, 316L, 2520, 31803, 904L molybdenum-titanium, carbon steel, heat-resistant steel, aluminum, and copper to produce various high-temperature and corrosion-resistant alloy flanges.

And we use high-quality raw materials like Inconel alloys (Inconel625, Inconel600, Inconel718, Inconel750, Inconel601), Incoloy alloys (Incoloy800, Incoloy825, Incoloy020, Incoloy028, Incoloy925), Monel alloys (Monel400, MonelK500), Hastelloy alloys (Hastelloy C-276, Hastelloy C-22, Hastelloy C-4, Hastelloy C, Hastelloy X, Hastelloy B-2), and super austenitic alloys (Alloy926, 254SMO) for our products. Ensures the quality of the flanges product from the source.

Our flange products are exported to Europe, the Middle East, North and South America, and Oceania, including countries like Germany, France, the Netherlands, Japan, South Korea, Saudi Arabia, UAE, Oman, Kuwait, and Canada. We enjoy a great reputation in both international and domestic markets. Please contact us if you have any needs.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....